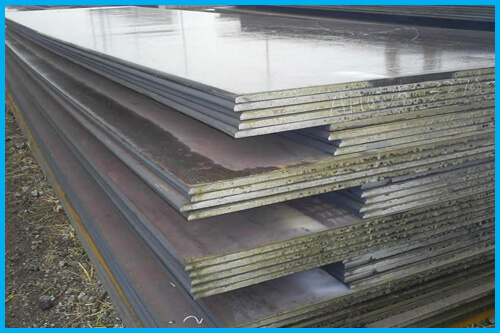

What is ABREX 500

ABREX 500 is part of Nippon Steel’s ABREX™ series, engineered for high wear resistance (approximately 500 HBW hardness) champaksteel.com+11nipponsteel.com+11csecplates.com+11.

Optimized for applications involving severe abrasion and impact, while retaining excellent weldability and formability nipponsteel.com+3prosaicsteel.com+3wixsteel.com+3.

Key Properties & Specs

Hardness: Around 500 HBW (~515 BHN typical) textronsteelalloys.com+1wearplates.co.in+1.

Thickness Range: Offered from ~4.5 mm up to 100 mm, depending on grade and manufacturer conqueststeelalloys.in+2textronsteelalloys.com+2multimetalsindia.com+2.

Chemical Composition: Includes carbon (≤ 0.35 %), manganese, chromium, nickel, molybdenum, and trace boron to balance hardness and toughness prosaicsteel.com+1dl.asminternational.org+1.

Mechanical Strength: Tensile strength in the range of 1,200–1,600 N/mm², with high impact resistance nipponsteel.com+5wixsteel.com+5nipponsteel.com+5.

Formability and Weldability: Good bending characteristics; welding requires appropriate preheating to avoid cracking tronixalloys.com+12csecplates.com+12multimetalsindia.com+12.

Advantages

Superior Wear Resistance: 3–5× more abrasion-resistant than mild steel – prolongs service life of equipment prosaicsteel.com+4nipponsteel.com+4textronsteelalloys.com+4.

Lightweight Design: Enables lighter structural components compared to using thicker mild steel, leading to economic gains .

Versatile Fabrication: Can be cut, welded, bent, and machined using standard workshop techniques conqueststeelalloys.in.

Typical Applications

Widely used in high-wear, impact-prone environments, including:

Mining & quarrying: dump truck liners, crushers, chutes, screens conqueststeelalloys.in+5prosaicsteel.com+5champaksteel.com+5

Construction & earthmoving equipment: buckets, blades, hoppers, conveyor parts prosaicsteel.com

Bulk-material handling: hoppers, scrapers, wear plates tronixalloys.com+4champaksteel.com+4prosaicsteel.com+4

Handling & Fabrication Tips

Use controlled preheating (often around 75–175 °C depending on plate thickness) to prevent weld cracking csecplates.com+2multimetalsindia.com+2dl.asminternational.org+2.

Adhere to welding guidelines—low impurity levels in ABREX promote good weld quality, but proper technique is essential multimetalsindia.com+2dl.asminternational.org+2nipponsteel.com+2.

Monitor for micro-cracks during forming or bending due to higher hardness and reduced elongation .

Quick Comparison

| Feature | ABREX 500 |

|---|---|

| Hardness | ~500 HBW (~515 BHN) |

| Abrasion Resistance | 3–5× that of mild steel |

| Thickness Availability | ~4.5 mm to 100 mm |

| Strength | Tensile ~1,200–1,600 N/mm² (est.) |

| Weldability | Good, with preheat |

| Formability | Good, but watch for cracking due to reduced elongation |

Manufacturers & Stockists in India

Available through authorized distributors like Prosaic Steel & Alloys, Textron Steel & Alloys, Champak Steel, Multimetals India, etc. nipponsteel.com+6textronsteelalloys.com+6wearplates.co.in+6multimetalsindia.com+3prosaicsteel.com+3textronsteelalloys.com+3.

Nippon Steel offers various ABREX grades including ABREX 400/450/500/600 and extra-tough LT variants nipponsteel.com+5nipponsteel.com+5multimetalsindia.com+5.

Summary

ABREX 500 is a high-performance, abrasion-resistant steel plate ideal for rugged, wear-intensive settings. It offers a prime blend of hardness, strength, weldability, and lighter weight—extending component lifespan and reducing operational costs. However, welding and forming require good practices and controlled preheat to maintain integrity.